INJECTION MOULDING

In the area of injection moulding we offer you State-of-the-art technology, in-depth expertise and comprehensive flexibility. With our ARBURG machine park and an experienced team, we realise your requirements with precision - from small components to complex hybrid solutions. Our aim is to supply you with plastic parts that are convincing in every respect: from the Shaping about the Material selection up to the Durability and sustainability.

Our ARBURG machine park

For high demands

In the Injection moulding area we rely on machines from the company ARBURG. This enables us to produce components weighing between 0.05 and 300 grams. Thanks to clamping forces of 50 to 220 tonnes, we offer a wide range of applications - from filigree precision parts up to Robust components for demanding applications.

Thanks to our automated peripheral systemsincluding Removal robot, Vacuum gripping systems and Packaging solutions we guarantee an efficient and repeatable production process.

Our variety of materials: the right polymer for every application

We use a wide range of materials to ensure that your products meet optimum requirements. Our standard materials include

- Polystyrene (PS) and Acrylonitrile butadiene styrene (ABS) for robust and easy-to-process parts

- Polypropylene (PP) and Polyethylene (PE) for applications that require flexibility and chemical resistance

We also process technical plastics such as

- Polyamide (PA6) for mechanically stressed components

- Polyoxymethylene (POM) for precise, low-friction applications

- Polyarylamides (IXEF)a high-performance plastic for applications with the highest demands on rigidity and strength

With a central material handling system, modern material preparation and -drying and the Residual moisture measurement of plastics, we guarantee that the polymers used are in the best possible quality flow into the production process.

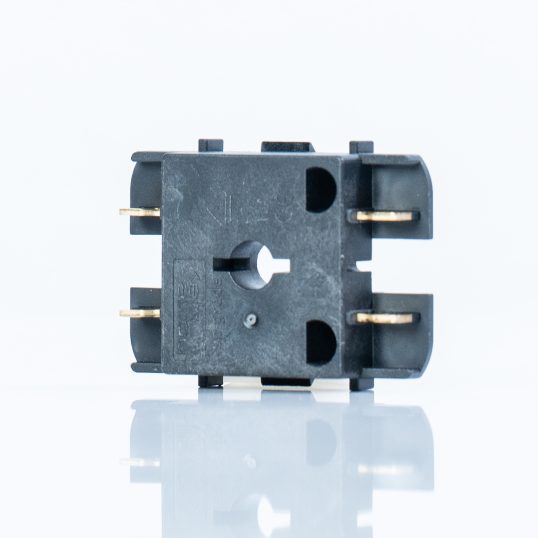

Hybrid technology

A Highlight of our injection moulding production is the processing of hybrid components. With the Insert and Outsert technology we combine plastics with different metals. The result: innovative components with outstanding functionality for a wide range of applications. Using automated gripping systems, we are able to Precise metal parts and Process reliable into the Injection moulding tool to insert.

Automation and efficiency

More than just machines

For Maximum efficiency and Consistent quality we rely on comprehensive Automations in the Injection moulding process. From component removal to packaging, intelligent, automated solutions ensure maximum precision and speed. Thanks to the use of state-of-the-art technologies and a Sophisticated process design we guarantee constant High quality standards - regardless of the batch size.

Your advantages at a glance

Efficient processes and responsible use of resources.

Reliable quality

Optimised material preparation and state-of-the-art testing methods.

From standard plastics to high-performance polymers.

Automated processes and precise machines.

Filigree components, stable constructions or hybrid solutions.

Efficient processes and responsible use of resources.

Reliable quality

Optimised material preparation and state-of-the-art testing methods.

Filigree components, stable constructions or hybrid solutions.

From standard plastics to high-performance polymers.

Automated processes and precise machines.

Why injection moulded parts from Friedenstab

The combination of technical expertise, modern equipment and customer-orientated service makes us a reliable partner in the field of injection moulding technology. Thanks to our high degree of automation we can offer you an economical production 100 % "Made in Germany" offer.

Do you have a project that we can realise together? Feel free to contact us to find out more about our services or to receive a customised quote.